When it comes to engineered wood glue down flooring, precision, patience, and preparation are key. A proper installation not only enhances the visual appeal of your space but also ensures the longevity and performance of your floor.

Recently, the team at Inovar Cape Town delivered an excellent example of how a professional glue-down installation should be done—featuring our stunning FINOAK Karoo engineered flooring. Let’s walk through the process and highlight the important steps involved in achieving a flawless finish.

Why Choose Engineered Wood Floors?

Factory stained wood floors are pre-stained perfectly with well known name brands such as Loba, Klump and American Wood Oil.

Factory pre-finished oak floors boast a better finish than homeowners or contractors can accomplish on site with the bonus that factory finished flooring is extremely durable and comes with a 25 year manufaturer warranty, saving you time and money on retreating your floor in the long term.

Subfloor preparation

Pre – Installation ensure the subfloor is level, clean, dry, and free of any old adhesives or contaminants.

Apply the adhesive correctly

Follow the manufacturer’s instructions for applying the adhesive, including the recommended amount and application pattern.

Choose the right adhesive

For the specific type of engineered flooring and subfloor. Follow the manufacturer instructions for applying the adhesive, including the recommended amount and application pattern.

Laying the Flooring

Begin installing the flooring, ensuring proper alignment, spacing, and fit between planks.

Fastening Pattern

Follow the manufacturer’s recommended fastening pattern to secure the flooring to the subfloor.

Test the flooring

Check the flooring for any defects, unevenness, or other issues.

Post-Installation:

- Inspect the installation:Verify that the installation meets the manufacturer’s standards and industry best practices.

- Provide maintenance instructions: Educate the homeowner on proper maintenance and care for the engineered flooring.

By following these guidelines and the manufacturer’s instructions, you can ensure a correct and durable engineered glue-down installation well done Inovar Cape Town on this stunning installation!

Installing engineered flooring like FINOAK Karoo is an investment in both style and substance. When done correctly by following manufacturer guidelines and industry best practices the result is a floor that not only looks exceptional but also stands the test of time.

Whether you’re a homeowner, designer, or installer, the key to success lies in preparation, precision, and using quality products. With its rich texture, rustic character, and superior craftsmanship, FINOAK Karoo is the perfect choice for those seeking timeless elegance and reliable performance.

Once again, congratulations to Inovar Cape Town it’s workmanship like this that continues to raise the standard across the flooring industry.

Warranties:

Warranties vary on engineered wood depending on the grade of the wood and the wood species. Domestic woods, such as maple and oak might come with a 10 to 20 year warranty. All FINoak product come with a 25 year manufacturer’s warranty.

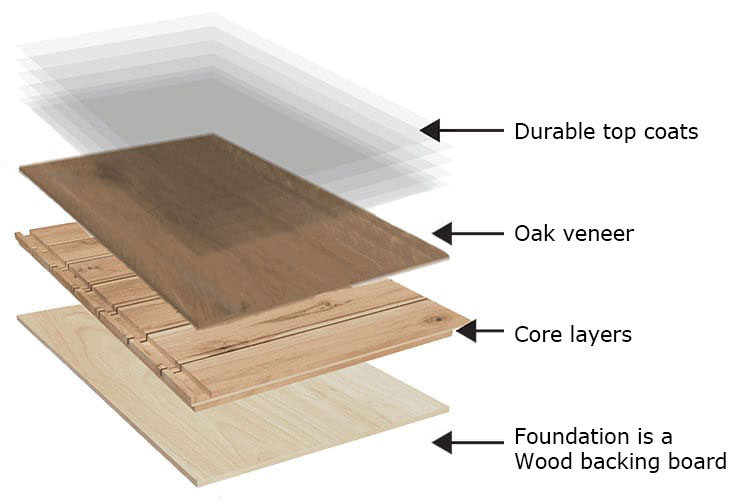

In general, engineered wood can be put throughout the house, requires less maintenance, is more moisture resistant, and generally at a lower cost – making it a popular flooring solution.