Today 3-ply engineered wood flooring is the most popular wood flooring option in Europe. Originally invented in the 1930 and Patented in 1940 by Kährs, one of the oldest wood flooring manufacturers in the World, the product quickly gained favourable momentum and broke through into global markets by the 90’s.

Let’s take a look at how this technological development has improved floor covering options.

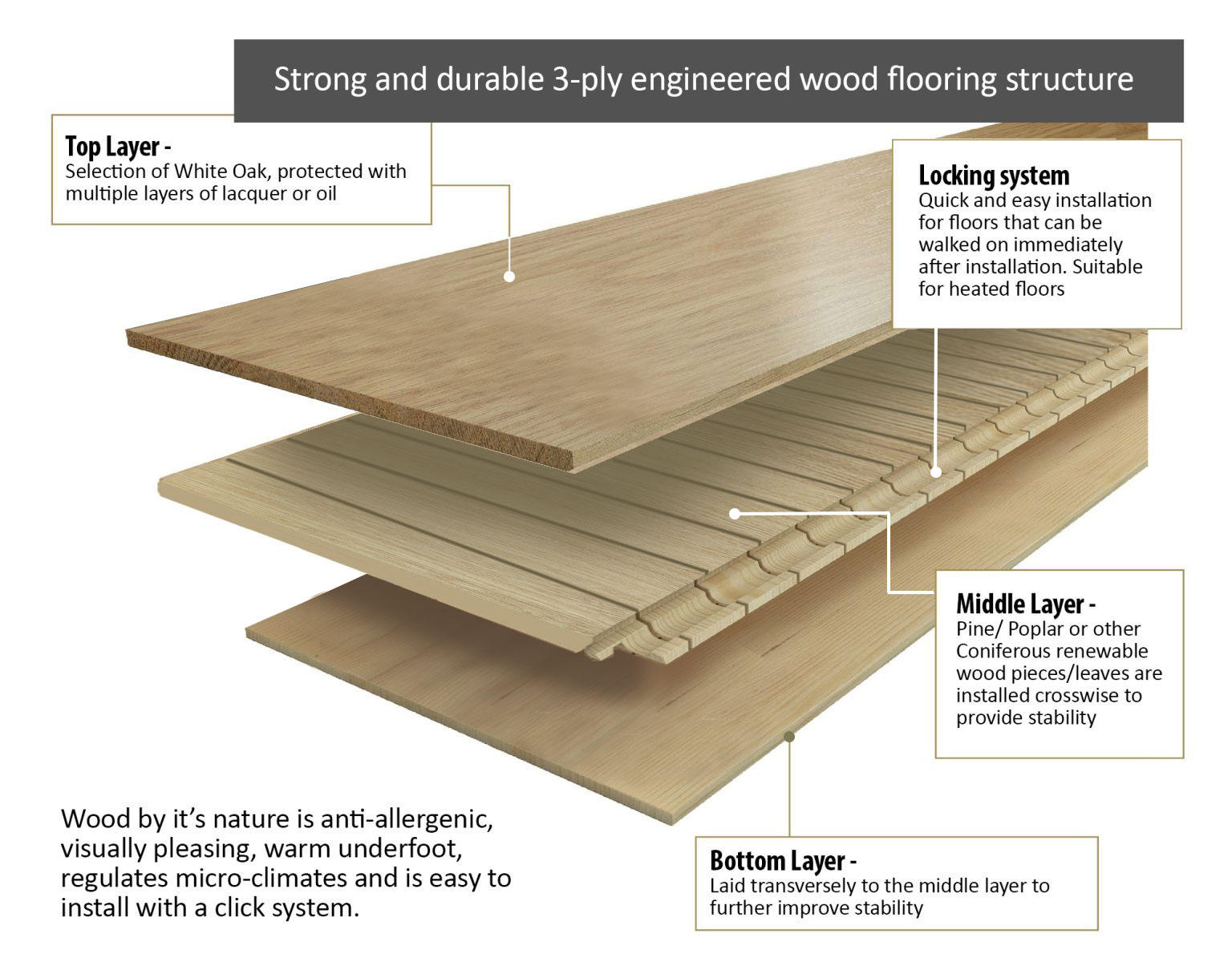

Structure

3-ply engineered flooring is made of 3 layers. A top layer of precious hardwood species, a backing board and a core made from a softer faster growing wood species. The softer material allows the top and bottom layer to expand and contract at the same rate, eliminating some of the shortcomings of standard 2-layer engineered floor. Such construction allows wider widths and longer lengths than would otherwise be typically possible.

Stability

A 3-ply floor achieves outstanding dimensional stability, and allows for installations at above or below ground level and radiant heated floors.

Due to the use of natural wood as the top veneer layer, core and backing layer, which is consistent with solid wood flooring performance and characteristics, but combined with super stability based on the criss cross structure. Every layer keeps away from the deformation, which is caused by the stress in variation of the temperature and moisture, it guarantees the dimensional stability of the floor.

Installation

These 3-ply flooring boards allow for an easy click system floating installation where the planks are not adhered to the subfloor or to each other. Thereby reducing installation time and cost whilst making future repairs easier.

Environmentally-friendly

As only a thin layer of precious hardwood is used in the top veneer more product is yielded per precious hardwood tree. Less of the worlds precious forests are affected as majority of the product is made from quick renewable plantation trees like Pine and Poplar.

Suitability

3-Ply Engineered Hardwood Flooring is more suitable for basements, conservatories or rooms that may be subject to humid or damp conditions. As well as being suitable for underfloor heating, as prescribed by the manufacturers guidelines.

Greater variety of natural REAL WOOD

The warmth and natural look of real wood floors have always been desirable. The top layer of real precious natural wood, defined by natures colour and patterning is unique. No two planks are the same. Unlike solid wood floors that are limited by real wood species, engineered flooring has embraced recent technology advancements in staining, textures, looks and finishes that are available, so you can now get a variety of finishes to suite vast taste requirements.

Affordability

With the decline of natural hardwood forests and the expense of solid wood flooring, engineered flooring is a more cost effective solution for both the planet and our pockets.

Long lasting

3-Ply engineered hardwood floor will last for up to 25 years or more. When needed it can be sanded down and re-treated to look as good as new or have a new look altogether.

In Conclusion

3-Ply Engineered Flooring is a popular alternative to solid wood flooring thanks to its superior stability, sustainability and suitability to various environments.

This method of construction and installation makes the floor stronger and more durable than other types of wood flooring, including solid wood and multilayer.

Together, this creates a floor that is affordable, durable, extremely stable and able to keep its shape in sudden or extreme temperature changes under certain guidelines, making it perfect for South Africa’s internal spaces with varying climatic conditions.