Facts

The difference between LVT and SPC

LVT vs SPC: What’s the difference?

When you think of vinyl, do you think of cracked and warped flooring in old-fashioned blue bathrooms and yellow kitchens? A lot has changed in the vinyl flooring market since the 50s and 60s: vinyl flooring evolved into thicker and more durable luxury tiles which could withstand a lot more moisture but also had the potential to suffer in certain conditions. Since the advent of vinyl flooring, there have been radical advancements in the construction technology of the planks, and common perceptions have not necessarily kept up to date with what’s currently on the market.

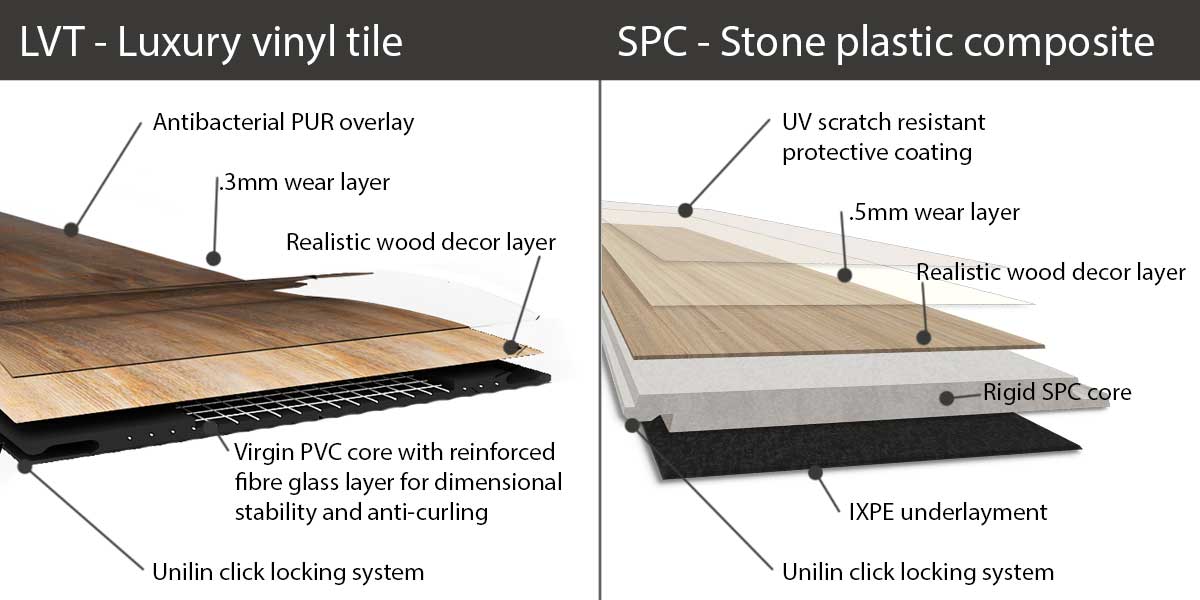

Luxury vinyl tiles (LVT) became very popular in recent times owing to their ability to withstand more heat than their update counterparts and to shrug off topical water, making them a good fit for kitchens and bathrooms. In the past couple of years or so, a new entrant on the retail/domestic scene has made waves in décor and flooring: stone plastic composite (SPC) flooring, which to date, is the ultimate vinyl flooring when it comes to dimensional stability, thanks to a core board fortified with stone powder.

With so many different vinyl products in the retail flooring space today, from glue down sheet, dry lay plank, click joint panels, it is sometimes difficult to make an informed choice about which is the most suitable product for your particular project. Check out the table below for a comparison of LVT tiles and SPC vinyl floors.

| Luxury Vinyl Tile | Stone Plastic Composite | |

| Construction | Has a cross linked fibreglass layer to increase dimensional stability and is rolled in layers which are fused together but it is still flexible. | Core is manufactured from Calcium Carbonate impregnated with lime stone mix, which is then manufactured using extrusion method. Less pliable and more rigid. |

| Plank thickness | 5mm or less | 4 – 6mm |

| Sturdiness | Little dimensional stability under exposure to direct heat and sunlight | Is sturdy under foot owing to a rigid core. It will prevent dents, wear and tear. Has a very high indentation resistance with greater wear ability properties depending on thickness of wear layer. |

| Appearance | Has a realistic look, but tends to be less advanced than an SPC vinyl. | Has a realistic look, possible texture and has a denser feel. |

| Sub-floor | Can be installed over plywood, cement and existing floors, but a traditional vinyl will not be forgiving with any subfloor imperfections. | Can be installed over plywood, cement and existing floors; an SPC vinyl will not change shape as easily as traditional vinyl. SPC vinyl has a limited chance of “telegraphing” & therefore more forgiving than traditional vinyl. |

| Installation | Can be glued down, can have a loose lay or click lock installation. | Can have a floating click lock, a tongue and groove system that is DIY-friendly. |

| Dent Resistance | Is soft and pliable, which means heavy furniture can easily dent the flooring. | Is more resilient when it comes to dents and heavy furniture. It is a great option for commercial settings. |

| Water proof | 100% waterproof against Topical water or pure uncontaminated water (i.e. from the top) | 100% waterproof against Topical water or pure uncontaminated water (i.e. from the top) |

Both LVT and SPC flooring definitely have their pros, both are 100% waterproof, available in a wide range of styles, and are easy to clean and maintain. From our perspective, LVT has failed in South Africa, for a number of reasons, not least of all, being lack of discipline by local installers in not following the installation instructions issued and because certain vinyl’s were not able to cope with the South African climate and our living conditions. A combination of our harsh South African sun, our cold winter nights, the lack of temperature control within our houses and lack of discipline made for all of the ingredients of a perfect recipe for cracking and lock failure.

SPC is the evolution of vinyl flooring that is built for South Africa. The high level of dimensional stability means that no acclimatization is required in the planks, and because they are so stable, expansion under direct sunlight of up to 50°C is no longer an issue. 6 Reasons to Install Diamond Core SPC in your Home or Office